China wholesale Power Transmission Chain Drive Factory – Single Roller Conveyor Chain For Glove Production Line – DEMY

China wholesale Power Transmission Chain Drive Factory – Single Roller Conveyor Chain For Glove Production Line – DEMY Detail:

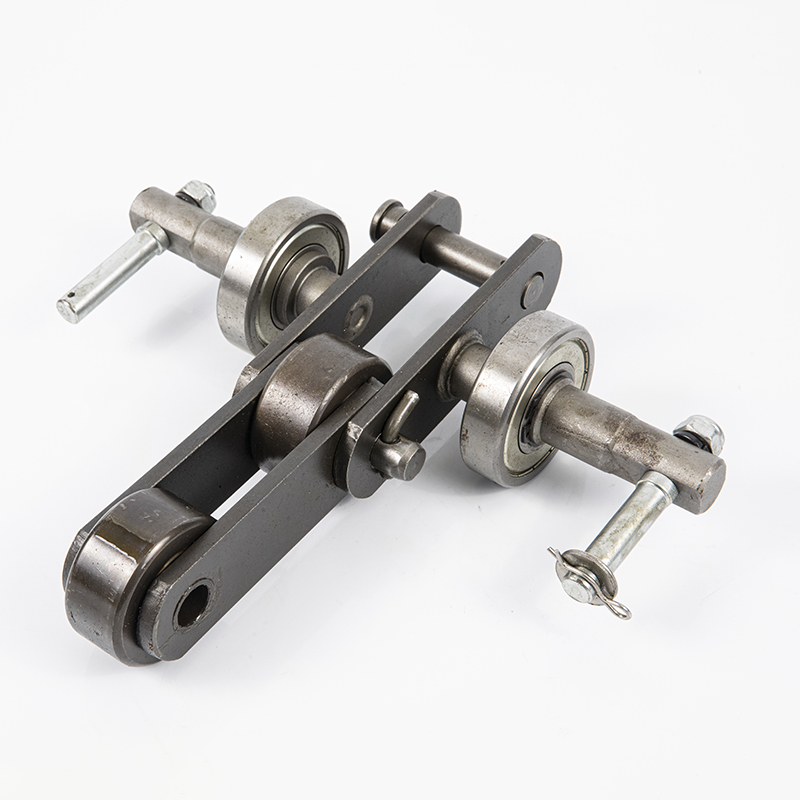

The conveying chain is the same as the transmission chain. The precision conveying chain is also composed of a series of bearings, which are fixed by the chain plate with restraint, and the positional relationship between each other is very accurate.

Each bearing consists of a pin and a sleeve on which the rollers of the chain rotate. Both the pin and the sleeve undergo surface hardening treatment, which allows hinged joints under higher pressure, and can withstand the load pressure transmitted by the rollers and the impact during engagement. Conveyor chains of various strengths have a series of different chain pitches: the chain pitch depends on the strength requirements of the sprocket teeth and the rigidity requirements of the chain plate and the general chain. If necessary, it can be strengthened. The sleeve can exceed the rated chain pitch, but there must be a gap in the gear teeth to remove the sleeve.

Problem handling:

Conveyor belt deviation is one of the common faults when the conveyor belt is running. There are many reasons for the deviation, the main reason is the low installation accuracy and poor daily maintenance. During the installation process, the head and tail rollers and the intermediate rollers should be on the same centerline as much as possible and parallel to each other to ensure that the conveyor belt is not deflected or slightly deflected.

In addition, the strap joints should be correct, and the perimeters on both sides should be the same.

In the course of use, if there is a deviation, the following checks must be made to determine the cause and make adjustments. The frequently checked parts and treatment methods of conveyor belt deviation are:

(1) Check the misalignment between the horizontal centerline of the roller and the longitudinal centerline of the belt conveyor. If the non-coincidence value exceeds 3mm, the long mounting holes on both sides of the roller set should be used to adjust it. The specific method is which side of the conveyor belt is biased, which side of the roller group moves forward in the direction of the conveyor belt, or the other side moves backward.

(2) Check the deviation value of the two planes of the bearing seat of the head and tail frame. If the deviation of the two planes is greater than 1mm, the two planes should be adjusted in the same plane. The adjustment method of the head roller is: if the conveyor belt deviates to the right side of the roller, the bearing seat on the right side of the roller should move forward or the left bearing seat should move backward; The bearing seat on the left side of the drum should move forward or the bearing seat on the right side should move backward. The adjustment method of the tail roller is just the opposite of that of the head roller.

(3) Check the position of the material on the conveyor belt. If the material is not centered on the cross section of the conveyor belt, it will cause the conveyor belt to deviate. If the material deviates to the right, the belt deviates to the left, and vice versa. The material should be centered as much as possible during use. In order to reduce or avoid the deviation of this kind of conveyor belt, a baffle plate can be added to change the direction and position of the material.

Product detail pictures:

Related Product Guide:

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for China wholesale Power Transmission Chain Drive Factory – Single Roller Conveyor Chain For Glove Production Line – DEMY, The product will supply to all over the world, such as: Croatia, Borussia Dortmund, Qatar, Many goods fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!