Glove Roller Chain Part Suppliers – Chain roller with customized size – DEMY

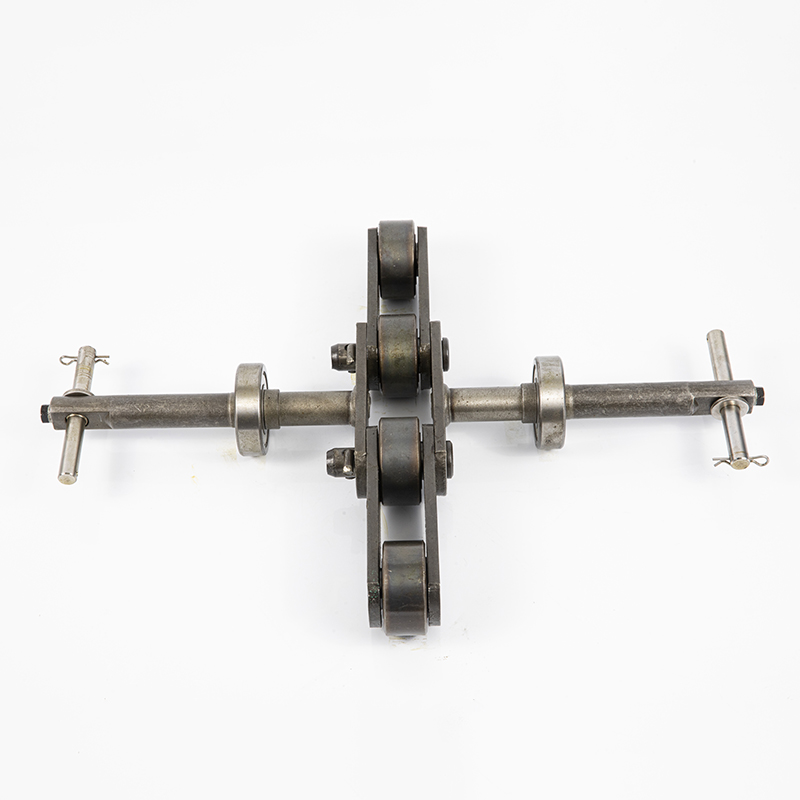

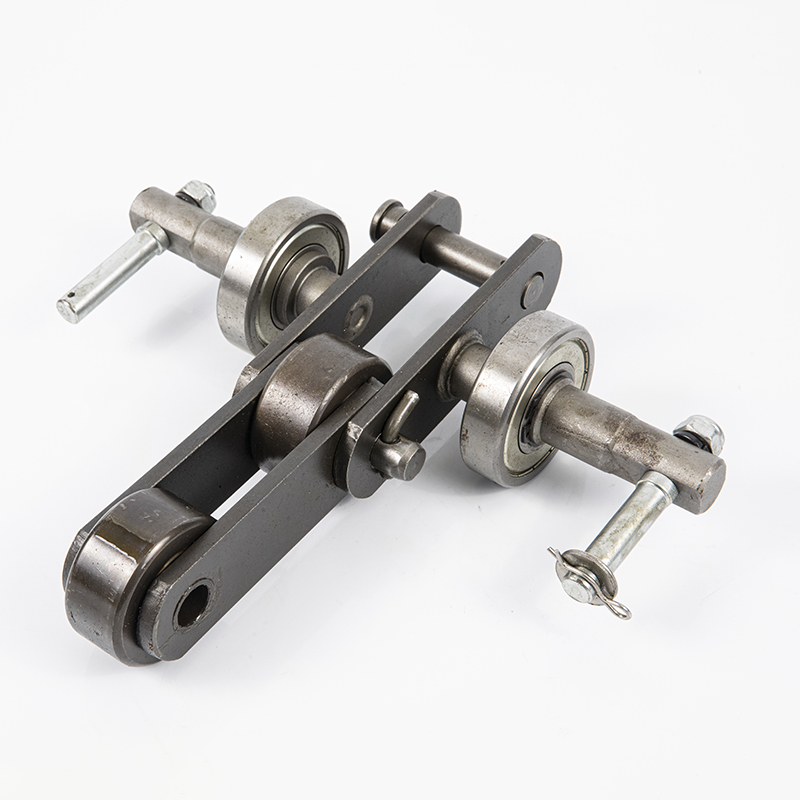

Glove Roller Chain Part Suppliers – Chain roller with customized size – DEMY Detail:

Problem Handling:

Conveyor belt deviation is one of the common faults when the conveyor belt is running. There are many reasons for the deviation, the main reason is the low installation accuracy and poor daily maintenance. During the installation process, the head and tail rollers and the intermediate rollers should be on the same centerline as much as possible and parallel to each other to ensure that the conveyor belt is not deflected or slightly deflected.

In addition, the strap joints should be correct, and the perimeters on both sides should be the same.

In the course of use, if there is a deviation, the following checks must be made to determine the cause and make adjustments. The frequently checked parts and treatment methods of conveyor belt deviation are:

(1) Check the misalignment between the horizontal centerline of the roller and the longitudinal centerline of the belt conveyor. If the non-coincidence value exceeds 3mm, the long mounting holes on both sides of the roller set should be used to adjust it. The specific method is which side of the conveyor belt is biased, which side of the roller group moves forward in the direction of the conveyor belt, or the other side moves backward.

(2) Check the deviation value of the two planes of the bearing seat of the head and tail frame. If the deviation of the two planes is greater than 1mm, the two planes should be adjusted in the same plane. The adjustment method of the head roller is: if the conveyor belt deviates to the right side of the roller, the bearing seat on the right side of the roller should move forward or the left bearing seat should move backward; The bearing seat on the left side of the drum should move forward or the bearing seat on the right side should move backward. The adjustment method of the tail roller is just the opposite of that of the head roller.

(3) Check the position of the material on the conveyor belt. If the material is not centered on the cross section of the conveyor belt, it will cause the conveyor belt to deviate. If the material deviates to the right, the belt deviates to the left, and vice versa. The material should be centered as much as possible during use. In order to reduce or avoid the deviation of this kind of conveyor belt, a baffle plate can be added to change the direction and position of the material.

Company Information

Exhibition

Certificate

Product detail pictures:

Related Product Guide:

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for Glove Roller Chain Part Suppliers – Chain roller with customized size – DEMY, The product will supply to all over the world, such as: Zimbabwe, Azerbaijan, Turkey, We've been always creating new technology to streamline the production, and give products with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to present our best service to satisfy all your needs! Remember to contact us right away!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.