Glove Former Holder Manufacturers – SUS Double Former Holder Set with D type disc – DEMY

Glove Former Holder Manufacturers – SUS Double Former Holder Set with D type disc – DEMY Detail:

As to give our very best to fulfill customer requirement, we manufacture our own products from high quality standard grade material with professional control work.The pursuit of excellence is the conception in our bearing production,it is also the conception in our former holder and chain production.

The special rubber seal researched & developed by our company,which adopts Japanese technology and with high temperature,it is more tough in higher temperature than ordinary NBR rubber seals,.The tight contact seal design avoids the chlorine gas, corrosive gas and particulate impurities entering bearing inside in the glove production process.we have promise this special bearing life is at least 24 months.

In addition we have advanced production line for former holder and roller chains.We are the first company in this field to apply semiautomatic or full automatic production machines and equipment.It ensures high quality and efficient production. If urgent production needed by our customer,

we can complete the production in a short time and deliver the product timely .Welcome all of you to visit our company!

In the factory dipping process, currently, the former is mounted onto the horizontal moving chain through a shaft which is connected to a former holder which can be rotated and tilted as required during the chain movement. These formers through the former holders are positioned in series along the conveyer chain.

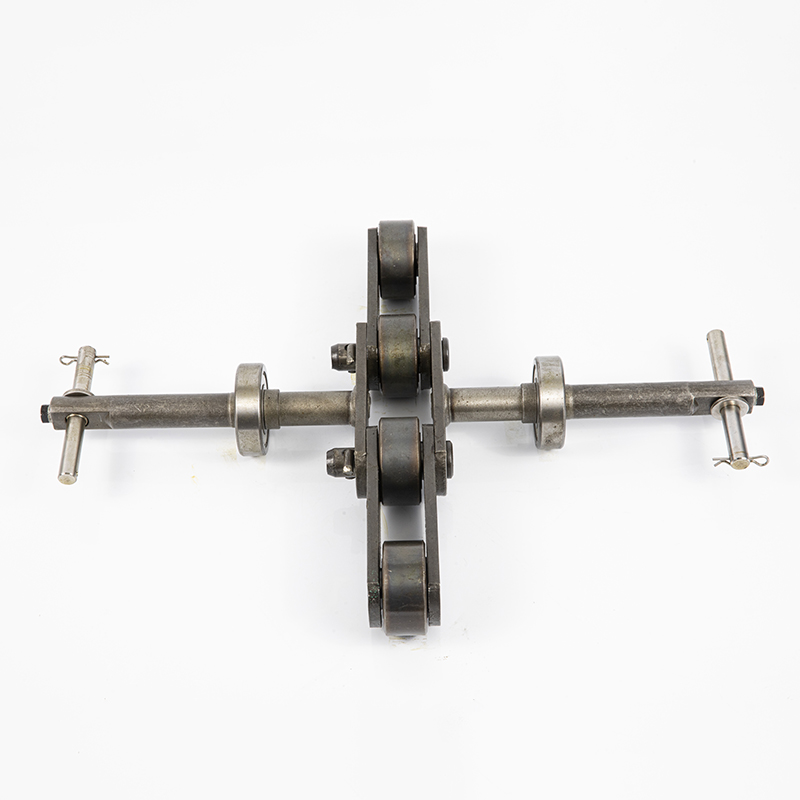

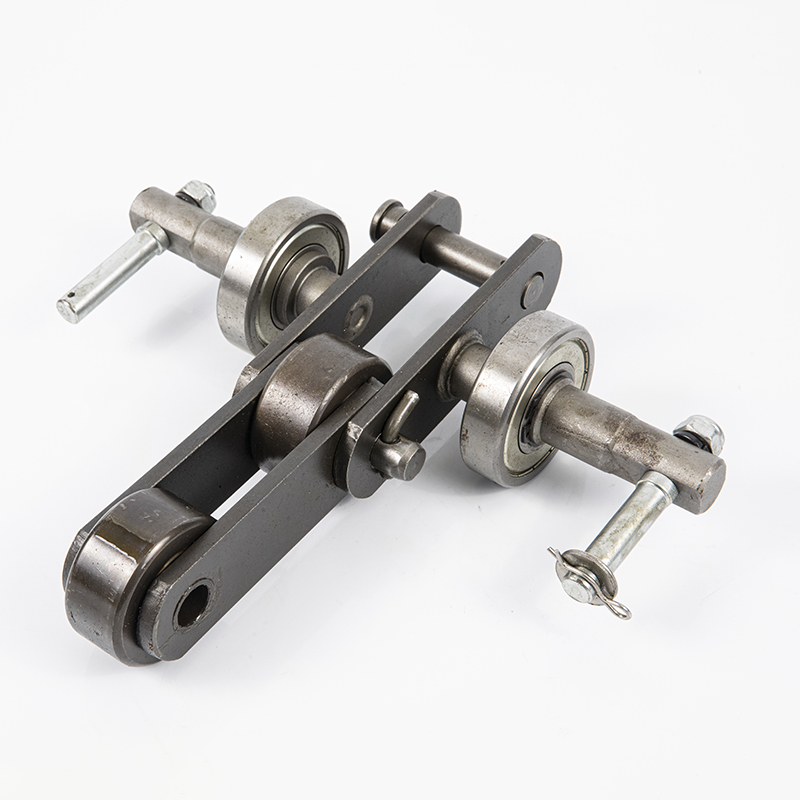

To increase the productivity, the former holder assembly is modified and designed by using more than one former at a single point of the moving chain. This is done through a former holder assembly which is designed to hold more than one former. Description of the prior art.

It will be advantageous in production if the conveyor chain can be used to accommodate sets of double formers. This can be done through the use of either a U-shaped bracket attached with two L-shaped arms each holding at least one former or a T-shaped pin which is attached to two hinges each holding a former, or the holders of formers are arranged in two tiers on both sides of the conveyor.

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Glove Former Holder Manufacturers – SUS Double Former Holder Set with D type disc – DEMY, The product will supply to all over the world, such as: Barbados, Ottawa, Gabon, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!